Green Credentials

As a business, we’re passionate about doing our bit for the environment. We believe that it’s important to protect our limited resources for future generations, and we’re making great strides towards making our business as sustainable as possible.

We want to be part of your carbon-neutral solution. From design and materials to sourcing and assembly, we drive the ethos of use and reuse. We’re constantly challenging ourselves to use innovative materials that minimise climate impact, resource depletion, and pollution, and we’re well on our way to making our products as green as we can.

The steelwork industry is determined to promote the material’s sustainable credentials, particularly the potential for reusing or recycling, but there are hurdles to be overcome. Steel may not appear to be all that “green” at first glance because of its strength and durability. However last year an estimated 650 tonnes were recycled annually, making it the world’s most recycled industrial material. Some 93% of structural steel gets melted down and recycled, with 7% reused, according to a European Steel Association survey.

Some of the ways we’re making our business more sustainable include:

Solar panels

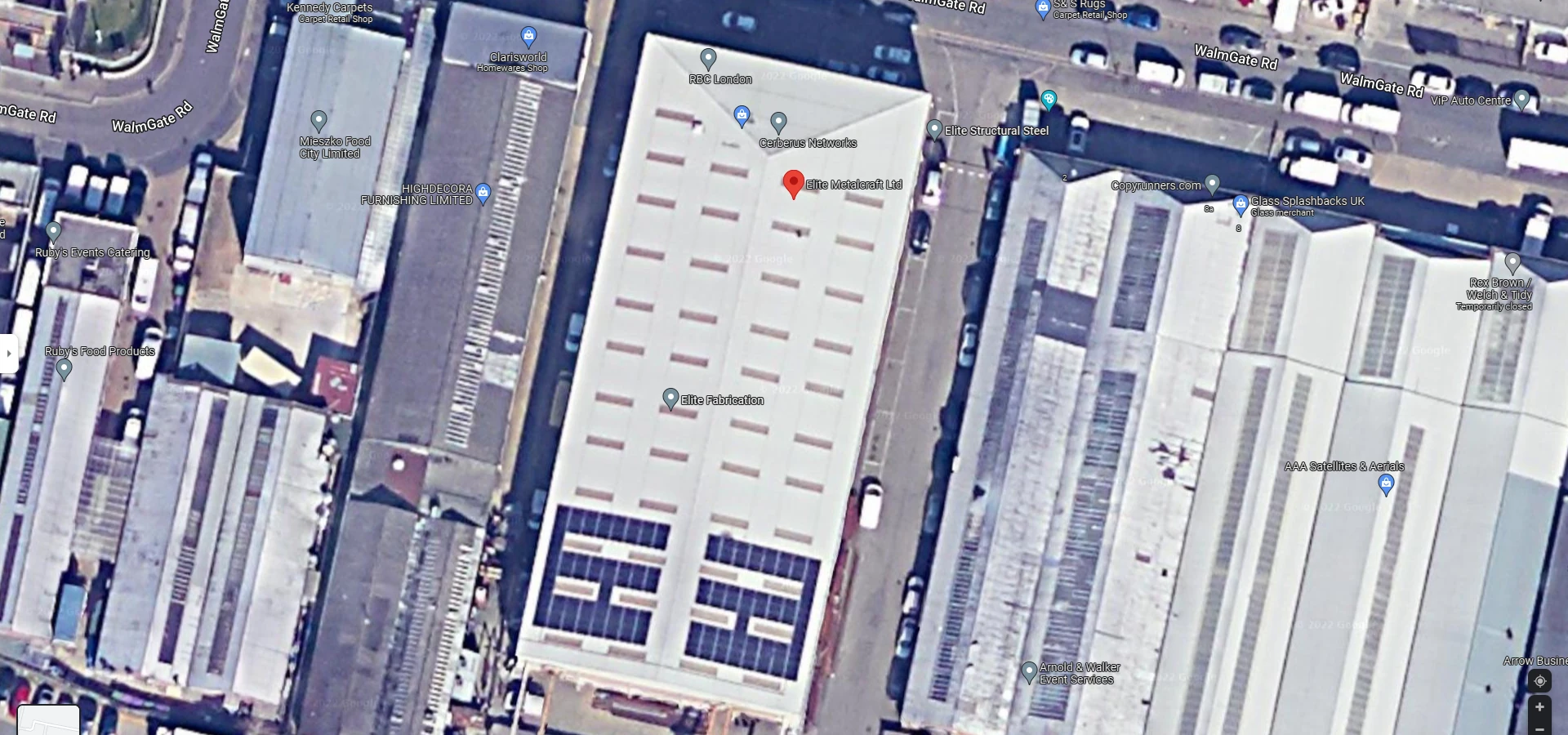

We are installing solar panels across our factory roof.

Fleet of vehicles

Modernising our fleet of vehicles to ensure that they are as efficient as possible.

Use and reuse

Innovative materials to minimise climate impact, resource depletion and pollution.

Recycling Partners:

We can’t do it all on our own. We’re steadily building a network of partnerships for closed loop remanufacturing, repair and recycling.

As we strive to do better for the environment, we hope that you’ll join us on this journey. Together, we can make a difference. If you’re looking for a sustainable solution, we’re here to help. Our team is knowledgeable and experienced in sustainable practices. Please book an appointment at our showroom to learn more contact us.

In need of a new metalworks partner? Get in touch.

Together, we can make a difference. If you’re looking for a sustainable solution to your project, we’d love to hear from you.

Why work with us?

70+ years of experience

Elite Metal Group has been manufacturing for over 70 years.

In-house manufacturer

Our 44,000 square foot factory in west London means our location is perfect for your project requirements.

Minimal lead times

By manufacturing in-house we can ensure that we meet every agreed project deadline with no delays.

No third parties

Our in-house teams can survey, design, manufacture, deliver and install.

40,000 sq. ft factory

Our factory in west London means our location is perfect for your project requirements.

Dedicated delivery fleet

Elite Metal Group has it's own in-house delivery and experienced installation Teams.

The Group Benefits

Our group buying power means that you can enjoy competitive rates whilst enjoying the best quality in the business.

Accredited

We're accredited by CHAS, Constructionline, BALI, FORS, CE Marking, Safe Contractor and more.