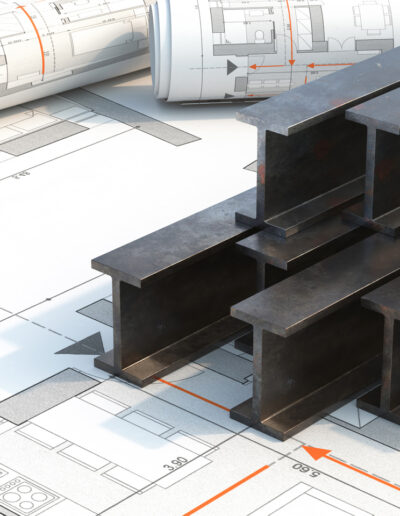

Steel fabrication

Folding and rolling of metal

Elite Metal Group’s metal folding and rolling equipment ensures we can meet a wide range of demands. Our staff of highly trained engineers can handle all sorts of projects, from single one-of-a-kind goods to big volumes and manufacturing runs. Using the most up-to-date press braking technology, we are able to provide a fast turnaround service with the accuracy that Elite Metal Group has long been recognised for.

The Amada Promecam HFB 170 is a 3-axis CNC controlled machine that can perform all kinds of operations, such as folding, bending, cutting, drilling and tapping

Key Stats:

Ability to bend metal over 3 metres wide with an impressive force of up to 170 tonnes.

Capable of folding up to 6mm thickness in all types of metal.

Features

- Ercolina TB50 Tube Bender.

- Sahinler 1550 x 140.

This machine is just one example of the many that we have at our disposal. Within the estate, we also have access to an Amada Promecam IT2/100 HFB 170-3. This machine is slightly smaller but no less versatile, and can be used for similar tasks when our factory is busy.

In terms of rollers, we have our Faccin 4HEL 3128. With 4 rolls this machine can be used for a range of purposes including plate bending, pipe bending, tank head forming and dishing and flanging. Rolling to a maximum thickness of 50.8mm with a power of 11.2k, it’s a robust bit of kit.

Elite Metal Group

The Elite Metal Group is known as one of London’s finest metal fabricators. For decades we have worked in partnership with customers fabricating and installing structural steel, bespoke structural and architectural steel projects. Whilst we dominate the construction sector, our teams have also completed projects in the transportation, energy and industrial industries.

But it’s not just experience and industry leading equipment that sets us apart. Our team at the Elite Metal Group are highly skilled professionals, constantly undergoing training to stay ahead of industry developments and advancements. This ensures we consistently deliver top-quality work for our clients.

Want to know more?

Why work with us?

70+ years of experience

Elite Metal Group has been manufacturing for over 70 years.

In-house manufacturer

Our 44,000 square foot factory in west London means our location is perfect for your project requirements.

Minimal lead times

By manufacturing in-house we can ensure that we meet every agreed project deadline with no delays.

No third parties

Our in-house teams can survey, design, manufacture, deliver and install.

40,000 sq. ft factory

Our factory in west London means our location is perfect for your project requirements.

Dedicated delivery fleet

Elite Metal Group has it's own in-house delivery and experienced installation Teams.

The Group Benefits

Our group buying power means that you can enjoy competitive rates whilst enjoying the best quality in the business.

Accredited

We're accredited by CHAS, Constructionline, BALI, FORS, CE Marking, Safe Contractor and more.